ProTips: How Important Are The Nozzles? June 05 2015, 0 Comments

The spray nozzles are a critical component of your parts washer.

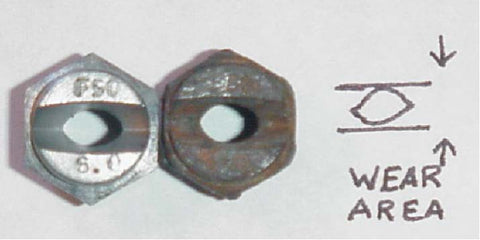

Over time the spray nozzle will become worn from the constant recirculation of grit, sand, sediment, etc. washed from the dirty parts. The sharp edges of the nozzle designed to control the spray pattern will dull and wear down.

In the image above, nozzle wear is not evident to the eye but this comparison shows a 3/64” wear. The Customer owning this particular parts washer had to replace the pump motor.

Why is this a big deal? The nozzle maintains the proper amount of back pressure on the pump in order to control the speed of the motor. Worn nozzles allow the pump to run too fast which, in turn, causes overheating, extra noise, and early failure.

A specific pattern of water is created by a spray nozzle in its proper alignment. This strategic placement is engineered to most efficiently clean your parts. When the nozzle's edges become worn, the water spray force becomes weak and sloppy, and that equates a longer time to clean the parts, lost energy, and efficiency.

Customers have reported after replacing their nozzles their parts washer cleans like it’s brand new again!

The pump manufacturer recommends changing your parts washer nozzles every two years. Since the replacement cost on a 3hp pump motor starts at $2015.00, ProLine, Inc. - Watertown highly endorses their recommendation!